72 Thunderbird Formula w/twin 165hp Mercs

Views: 2386

- Attachments:

Replies to This Discussion

-

I cut a hole in the floor of the cabin so I could tab in the rear of the front bulk head to the hull. I attached a layer of 3/4" ply under the floor before I installed the bulkhead to strengthen the floor not that it needed it because once I cut the hole I realized it already had a piece of 3/4" ply in place from the factory. Now it has

1 1/2". I have a new hatch to place in the hole that measure 10" by 14". Gives me an inspection port as well as another small storage area.

-

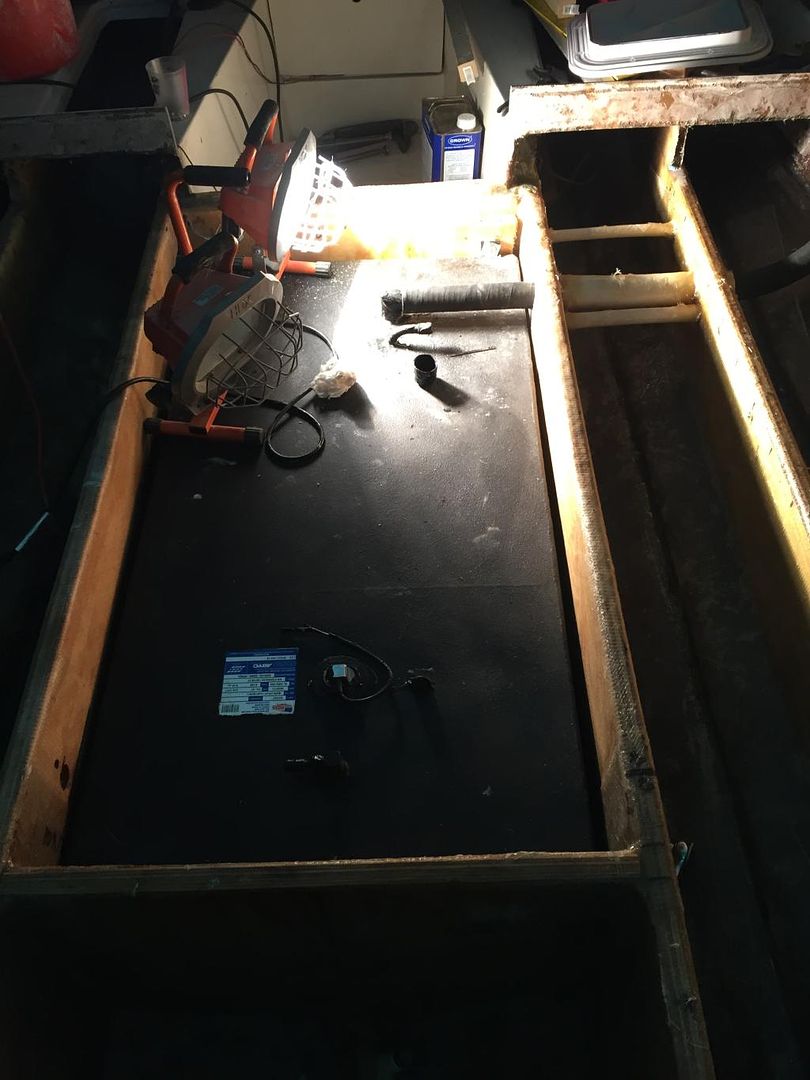

Still playing catch up on here. I got the tank installed. I should have taken pictures of it as I installed it. The tank was originally a 110 gallon. I had a new one built that is about 64 gallons I think. I had them coat it in cold tar and I sprayed another coat on it myself. The tank rested on two 2x2's running fore to aft so I installed this one the same way except I bedded them a lot better in PB and covered them with CSM and 1708. I then matted Nylon strips the length of the 2x2's so the tank was resting on the nylon not the wood. The strips are about a 1/4" thick and 1" wide and held down with 5200. I then put a think coat of 5200 on top of the nylon so the tank would be bedded down onto the nylon and hopefully no air or water gets between the tank and the strips. The original tank was encapsulated in foam. That was the only foam that Formula put into this boat and after reading everything about foam and aluminum tanks and seeing what it did to the old tank I decided not to use foam on this one. The tank sits in the coffin only touching on the bottom and front and rear brackets. On the front and rear brackets I used SS lag screws into 2" of plywood that is covered in CSM and 1708. I used more of the nylon strips as washers again keeping the tank from actually touch wood. When the factory installed the original fuel fill, vent and supply hoses they just cut out oversized holes or notches in the bulkheads and stringers. They didn't even seal the wood. This time I cut clean holes through the stringers and used PVC pipe to run the hoses through. I sealed the PVC pipes in PB between the wood and PVC. I used a flexible permatex where the hose goes through the pipe sealing it up on both side so water cant intrude through those areas. Once the deck is in place the only way water can get in is through the 4" screw in deck inspection plates I will install over the Fill & vent hose on one side and the supply hose on the other side. I also installed another 4" inspection plate low down on the rear bulk head so I could occasionally look under the tank at the aft side where water would collect if it was to get into this area.

-

-

Looks great.. why the bulkhead splitting the fuel tank area?

I have recored the entire fwd deck on my 64 233, now raising cockpit sole 4". Have moved hyd trim units and batteries fwd almost to main bulkhead. Cutting weight as much as possible.

Power is 2 3.0 MC's.

Making entire sole watertight, Gasketed hatches, 3" scuppers with shut off valves. 2" regular scuppers. Have a 6" dam gasketed to sole inside engine box so water has to go out the 3" scuppers before it gets over the 6" dam.

This hull was cored above the chines, and kept in dry storage for 50 years.. only damage was balsa deck cores from cleats, anchor chocks, pulpit mounts. All hardware mounts are now backed by meranti ply, not balsa.

Goal is light, economy fuel burn, capable of taking green water and putting it back where it came from.

-

Arthur, thanks for checking in, a 1964 233 that's awesome post some pics. As far as the bulkhead on the front and rear of the fuel tank bay that is how it was built. The original tank was about 110 gallons and 6 feet long. The new tank is only 4 feet long and about 67 gallons so I had an extra 2 feet of space between the main stringers so I made 2 compartments. One is a fish ice box that is a little larger then the other compartment which will be storage for extra anchor and lines. The old tank bay had 1/2" plywood bulkhead front and rear but the area was not sealed very well and the tank was encased in foam and as a result of the moisture intrusion over the years the tank was pitted and leaking. The new tank bay is sealed very well. It has been sealed for months and I have washed down the boat several times with a garden hose spraying water everywhere. Monday I opened the inspection port I put in the rear bulk head so I could check the inside bottom rear part of the tank and compartment, it was dry as a bone. I am expecting some moisture in there as a result of condensation from the temperature variance in the fuel when I fill up but I don't think that will be an issue, I hope. As far as the weight I went the opposite way you are going. I added beefier stringers, bulkheads, deck. These twin in line 6, 165hp push this tub pretty well not a speed boat by no means but when it was running I could do about 46mph with just me and 20 gallons of fuel and the standard gear I would have on board. The cool part was I could then load it down with 4 divers and all our dive gear and 12 tanks enough for 3 dives and still be able to get up to about 42mph WOT. As far as fuel economy its a boat and never cared too much about GPH. Good luck on your resto and again post some pics.

-

I screwed up and didn't have any drain lines for the spaces between the inner and outer stringers. This area is about 10' long and 15" wide and runs from under the cabin seats to the rear bulk head. My plan in this area was rod storage with access from the cabin or from the cockpit deck so water is going to get down here and needed a path to drain down into the bilge. So I rigged up some PVC pipes and 5/8 rubber hose. The PVC is sealed in PB so if it works as intended water will drain to the rear of the rod storage area and then down to the main bilge drain and end up in the bilge.

-

Ok I have all the bulkheads installed and installed 2x4 braces that run port to starboard. 3 of the supports will be where the seams are going to be on the deck. With all the stringers, bulkheads and bracing I shouldn't have any flex issues with the deck which will be 3/4" ply covered underneath with a layers of CSM then bedded to everything with PB and 2" SS screws. On the top it will be PB on the sides tabbed in with CSM and 2 over lapping layers of 1708. I was then going to cover the deck in 2 layers of 1708 covered by CSM.

-

I also cut out 2 of the 3 deck pieces of plywood. It will be weird having a deck to walk on. Then it will be time to start rebuilding those Chevy 250 Inline 6s. Funny thing on the engines. I still have one of the original engines which I was going to use for parts or even a spare. I also have 2 engines and stern drive packages I found bought last year as well as two long blocks for spares. I ran all the block numbers to see what year they are from and found out that the engine out of the boat is not a 250 it is a 292. My dad always thought both engines were 250 cubic Inch engines and we could never get both engines to top out at the same RPM range at wide open throttle. Knowing that one was a 250 and the other is a 292 might have explained that one

-

Cleaned out the garage and sorted through my engines getting geared up to start working on those. I pulled the heads off the 2 donor engines I got last year so I can rebuild them. On one of the engines I pulled the manifold off and hiding behind it was a 12" long crack in the block with JB weld not holding it together. No big deal I have 2 more blocks I can use and everything off that engine looks great (Elbow, Manifold, head, carb, oil pan, fuel pump, alternator, starter, distributor, stern drive, trim pump, crankshaft, cam shaft and on and on) so it was still a great deal on the package. Stripped everything off of it and know have a 150 paperweight waiting to go to the scrap yard. I still have the donor boat and trailer I have to sell as well.Making a list of supplies I ordered, used and wish I would have gotten more or less of. Back in September last year I placed my order of fiberglass supplies at US Composites. Now this is for my 23 foot boat. Complete restoration of deck, stringers, transom. Also the first time ever fiberglassing anything so there was wasting at first and still is a little.

50" wide 50 yards of 1.5oz Chopped Strand Mat (CSM) I have used about 25 yards of it. Should have ordered 30 yards

50" wide 30 yards of 1708. I have used all of it and picked up 10 more yards at my local place

Resin 20 gallons used it all and have since picked up 15 more gallons from my local place, used 7 of that so far

Epoxy 1 gallon kit have not used it yet

2lb flotation foam. 1 gallon of each "A" "B" mix. I wont be using

3m Glass bubbles 2.5 quarts. I have not used them yet

Fairing compound 2.5 quart I have not used it yet

4 gallons of Acetone I bought from HD or Lowes. Used that and bought 1 more gallon

2" chip brushes. Bought 24 which I have used. Got about 15 more and used most of them.

2 tubes of 3m 5200. Used 1 so far

Cabosil. 4 gallons used that. Ordered 5 more quarts used that. I picked up 2 more gallons from local place and have about 1.5 gallons left

1/4" chopped strands. 4lbs I have 1/4 pound left

Stir sticks. ordered pack of 50 used most of them

Tongue depressors ordered 50 pack and have used about 15 of them

Plastic 1 quart mix cup. Ordered 50 used about 25

Plastic 2.5 quart mix cup. Ordered 25 used all of them. I have probably picked up 20 more and used them

Plastic 5 quart mix cups. Ordered 25 used all of them. I have probably used 10 more

Gloves. 100 per box and I have used 5 boxes

Tyvek suits for when I was grinding at least 4. I ordered them on line. I liked the yellow suits with the hood and booties. Order the biggest size they have.

Full face mask I had one but went through several sets of the high dollar charcoal filters. Finally started using the cheaper filters I pulled off of the mask I got at HD. They have cotton pads that come off and can be cleaned easy so I was able to use those filters a lot longer before I had to replace

4" roller handles. Went through at least 20 of these. Really started trying to clean them after each use and am able to use them several times before I have to toss them

4" rollers. I ordered 36 which are gone. I have since started buying the large packs of 9" rollers and cutting them done to two 4" rollers using my chop saw.

I should have ordered a little more 1708. Less 1.5oz CSM. I should have ordered some 8oz clothe. I needed a lot more of the mixing cups. I started cleaning out used cups and reuse them to mix the PB in. Hindsight on the Cabisol I made a lot of PB so I used a lot of Cabisol. Should have ordered more. The foam I ordered before I tore out the deck and found out the only place Thunderbird used foam in these Formula 233 was around the fuel tank and I decided not to repeat that mistake so I don't need the foam. Anyway just a rundown of what I have used. May help someone out when they plan their orders.

© 2025 Created by David.

Powered by

![]()